Wire

We can provide wire products for many different applications in corrosion-resistant and high temperature alloy wire, Stainless steel and Nickel alloys. We supply sizes ranging from .05” to .625” in rounds and up to .375” in squares and hexes, in tempers annealed through full hard. We offer a variety of packaging, including coils, spools, reels and straightened and cut in lengths up to 12 ft.

Wire Alloys

| Alloy | Sub-type |

| Stainless Steel | 302,304/304L, 305, 310, 316/316L, 317/317L, 321, 330, 347, 410/416/430, 17-4Ph/17-7Ph |

| Nickel | 200, 201/205, 800, Alloy 400, Alloy 600, and Alloy X750 |

Wire Applications

- Antenna Wire

- Belt Wire

- Brush Wire

- Dental Wire

- E.P.Q Wire

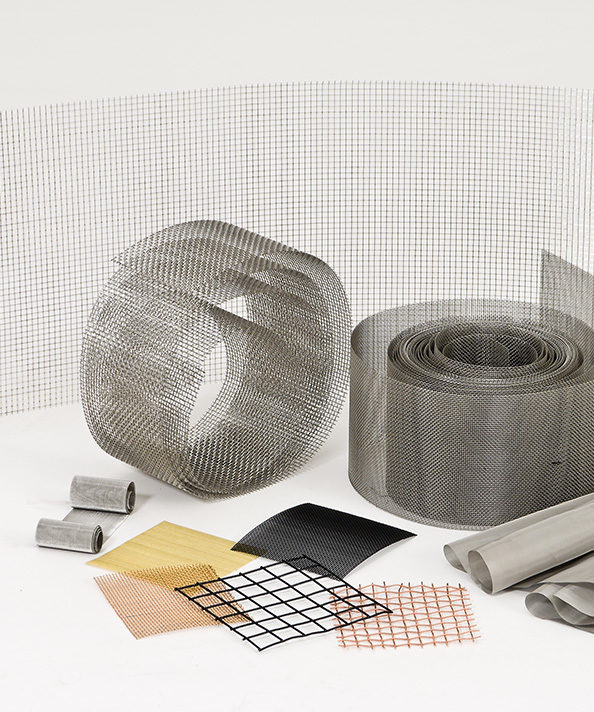

- Filter Wire

- Forming Wire

- House Wire

- Knitting Wire

- Medical Wire

- Orthodontic Wire

- Pin Wire

- Rod Wire

- Safety Lock Wire

- Shaped Wire

- Spring Wire

- Tag Wire

- Tie Wire

- Weaving Wire

Wire Packaging

Wire Specifications

We meet the following specifications:

- MS20995C

- MS20995N

- MS9226

- AMS5689

- AMS5643

- MS20995CY

- MS20995NC

- 302 Condition A

- 304 Condition A

- 305 Condition A

- 316 Condition A

- 321 Condition A

- QQ-W-423

- QQ-W-390

- QQ-N-281

- Alloy 600 Annealed

- Alloy 600 Oxide Coated

- Alloy 400 Annealed

- Aluminum 5056

- Copper QQW-343 Type 5

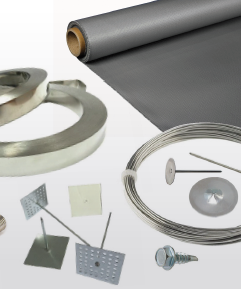

Safety Lock Wire

Safety Lock Wire is threaded through fasteners to counteract the torque force of a fastener attempting to undo. It has a wide variety of applications where failure cannot occur – such as mission-critical flight controls, throttle assemblies, or safety guards. Our wire is supplied in standard 1lbs. spools or handi-cans. Larger spools are available upon request. We are able supply to all lock wire specifications including those compliant with the DFARS special metals clause. (Please specify DFARS compliance when requesting either a quote or an order).

Tie Wire is fully annealed wire for use in the construction and insulation industry. Gerard Daniel’s annealing process continuously produces a soft, but strong wire, giving it the flexibility that is necessary for quick tying and the strength to hold. Recommended to be employed in bundling or securing products such as insulation, wire, rod, lumber, PVC tubes, pipe, and rebar. Common Alloys of Tie Wire are Stainless Steel, Galvanized, Black Annealed, Copper Coated, and PVC Coated.